Casting squares & rectangles

The simplest shapes made with ShapeCaster Angles are squares and rectangles.

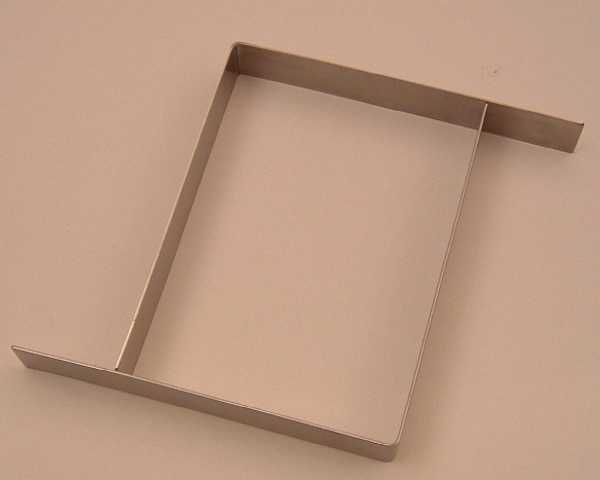

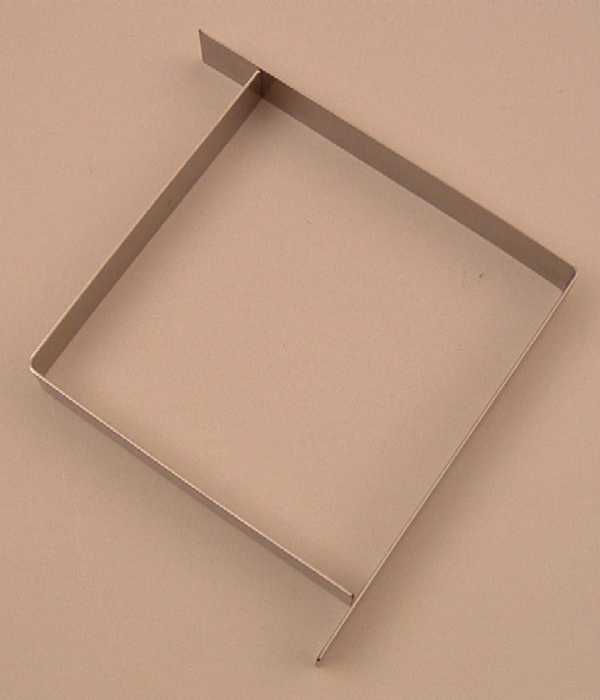

Squares: Nesting a smaller Angle inside a larger one (as pictured) is the easiest way to make a square.

Rectangles: Two same-sized Angles make a rectangle. Using this technique, the angle size determines the longer side and the shorter side length is adjusted by sliding the angles horizontally.

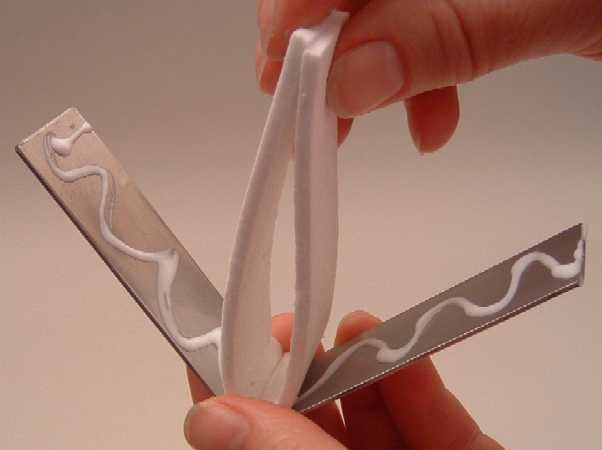

Cut a fiber strip a little longer than the inside surface of the Angle, and longer than the edges of your casting that it will contain. Fold it in half, clip the end with a spring clip to keep it folded, and set it aside. Next, run a line or series of glue dots on the inside of the angle, as pictured (you can put glue on the fiber instead, if you wish.) Be fairly generous with the glue.

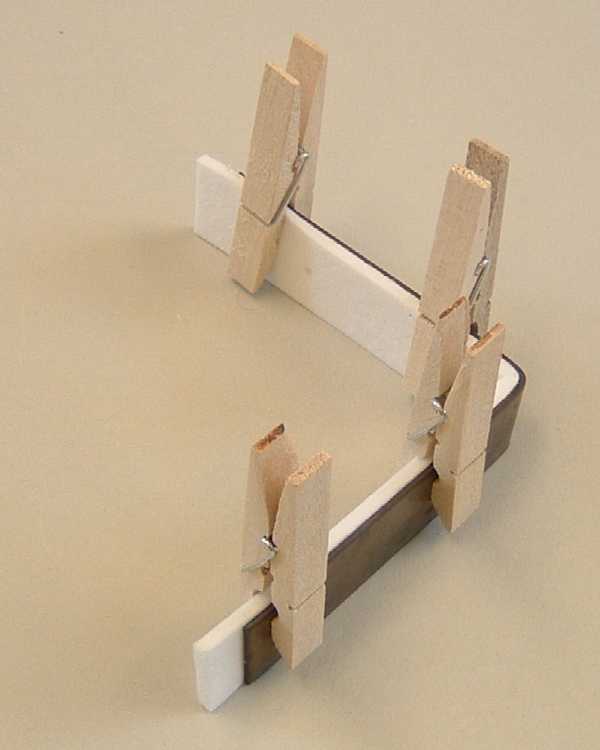

Tuck the folded edge of the fiber into the inside corner of the angle, remove the clip, and smooth the fiber against the inside edge of the angle. Place the angle on a flat surface (preferably NOT your kiln self) and push the fiber down until it touches the surface evenly along the angle. It's best to do this on a tabletop or or other clean surface to avoid getting glue on your kiln shelf. Place a few clips to hold the fiber in place, and set it aside to dry (5 or 10 minutes.)

Repeat this process with the other angle. Be sure to let it dry before proceeding.

Remove the clips. Actually, you can remove the clips at any time during assembly. Clips can help hold your form together while you're placing the glass; it's OK to add more for this purpose. Just remember to remove them before you turn on your kiln.

Dry fit your angles and check the inside dimensions with a ruler or tape measure.

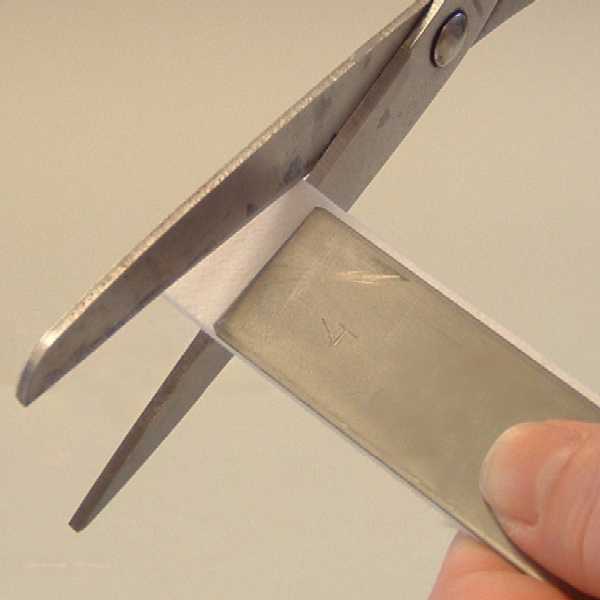

Trim the fiber ends to size. Ideally, fiber should extend slightly past the metal. Make sure your cuts are straight and perpendicular to the fiber edge.

Place the angles together on your kiln shelf, nested for a square or parallel for a rectangle, as pictured earlier.

Avoid gaps in your shape by making sure fiber touches fiber at the ends of each angle.

Place the glass you’ve selected inside the shape. Check to make sure no gaps have opened between your angles after you’re done.

Bracing the sides of large angles with kiln furniture or another Angle is sometimes helpful.

Fire and anneal using a kiln profile appropriate to your casting. We'll cover this separately later.